YX667HV Ensign Wheel Loader

ENSIGN builds one of the Asian largest integrated production plants to produce qualified wheel loaders with high-technology. 80% components and parts are made here by using various advanced facilities with strict quality control to ensure the quality of machines. Flexible production line and lane manufacturing can satisfy diverse demands of customers.

Epitomize the highest levels of performance and productivity.

Ensign

YX667HV Wheel Loader (Diesel)

Perfect Match with High Performance

Powertrain and hydraulic system are matched perfectly, which makes the loader easy to operate and the work efficiency improved dramatically, both will significantly increase the loader's productivity. Reinforced structure and qualified parts make the loader more reliable, which increase the loader's service life and thus profit customer greatly.

Unique Hydraulic System Design

Dual-pump converging hydraulic system can improve the loading power and speed significantly when loading the materials, and reduce the steering fatigue when operator turning the machines. Equipped with hydraulic accumulator which can dramatically improve the system reaction speed and increase whole system working efficiency.

Short Working Cycle Time

The machine's working cycle time is less than 10.2s, which ensures it can load more materials in short time. Pilot joystick function can both improve working speed and reduce fatigue to operator.

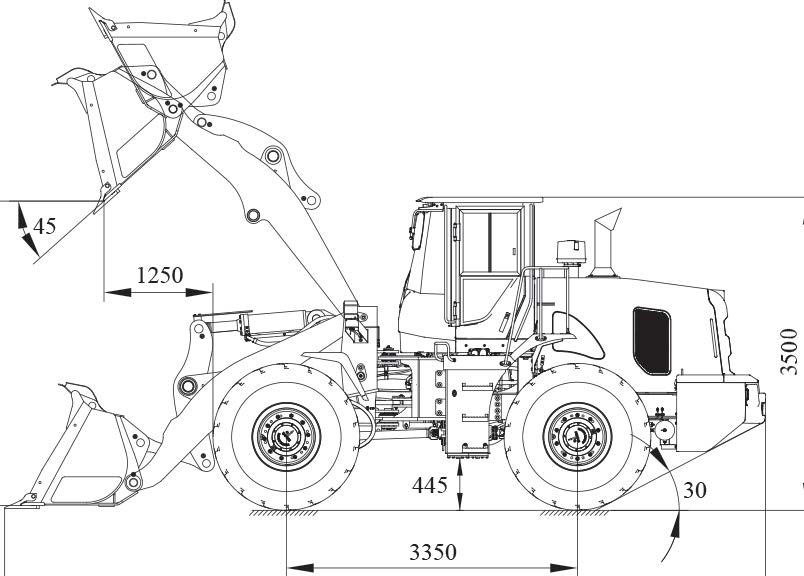

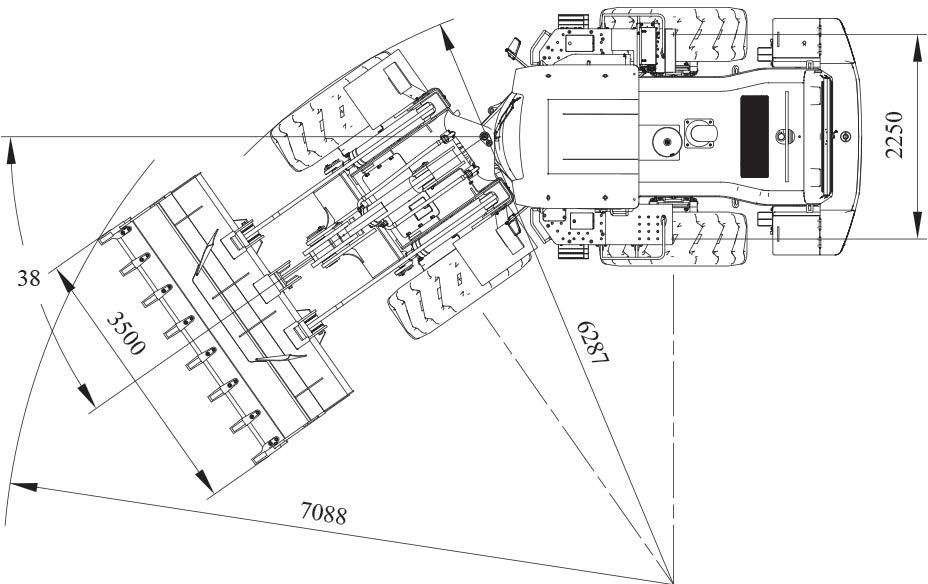

Z- Bar Linkage and Bucket

The proven Z-bar linkage with series of high-performance buckets provide excellent insertion into the pile, large breakout force, good roll back angle and fast digging. The results are improved production capabilities, these also help to enable a sustainable solution for your business.

More Reasons to Choose WWTEG

Get a free quotation now!